COURSE OBJECTIVES

At the end of the course, the participants should be

able to:

- Explain the fundamentals of instrumentation and

process control system as used in the industry: - Design and install practical instrumentation

systems to get accurate feedback from

production processes; - Calibrate and repair test instruments, gauges,

transmitters, transducers, valve positioners, etc.; - Identify and give remedy to common quality

process problems.

COURSE CONTENT

The course will have a total of thirty-six (36) hours and will cover the following topics:

Module I: Introduction to Instrumentation & Process Control

- Process Control Principles

- Elements of Process Control

- Control Loop Operations

- Standard Symbols and Diagrams

Module II: Industrial Measurements

- Sensors and Transducers

- General Principles & Measurement Practices

- Industrial Pressure Measurement

- Industrial Flow Measurement

- Industrial Level Measurement

- Industrial Temperature Measurement

Module III: Receiving Elements

- Pneumatic Controllers

- Electronic Controllers

- Typical Functions & Trouble-Shooting

- Microprocessor-Based Process Controllers

Module IV: Final Control Elements

- Selection of Control Valves and Other Final Control Devices

- Operation, Maintenance & Repair of Control Valves

Module V: Calibration & Testing

- Repair and Calibration Techniques

- Calibration of Gauges, Transmitters, Transducers,

- Valve Positioners, Controllers, etc.

TARGET PARTICIPANTS

Preferably, the participant should be a holder of a bachelor’s degree in mechanical, electrical, electronics, industrial or chemical engineering. The course is also open to instructors of technical schools as well as industrial technicians.

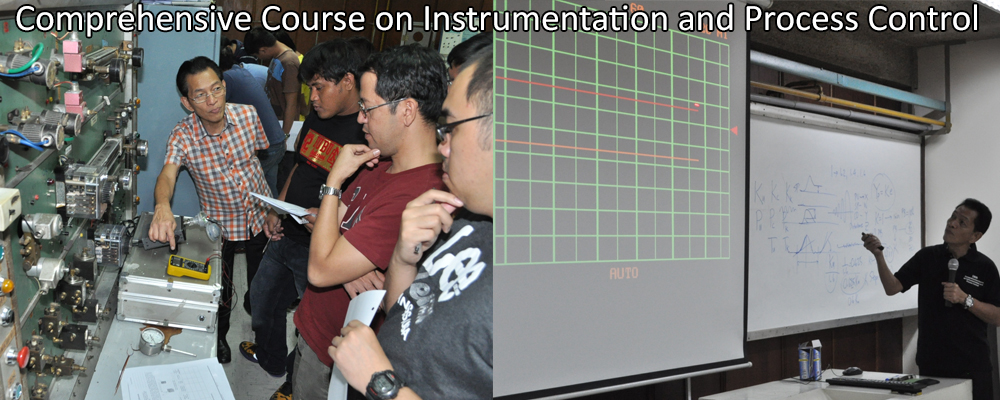

TRAINING METHODOLOGY

The concept of Industrial Automation and Instrumentation will be introduced through the teaching of principles and simulation of their industrial applications in the laboratory. Repair and calibration techniques on various instruments will be the highlights in the laboratory portion.

VENUE

Sessions will be conducted in the Low-Cost Automation (LCA) Rooms at the ground floor of UPISSI.

PROGRAM COST: TBA

Tel. Nos.: UP trunkline 8981-8500 local 4054